MSC GREEN-12 Clean Air gas-insulated Switchgear

MSC GREEN-12 Clean Air gas-insulated Switchgear, it is a new design and development of gas-insulated metal-enclosed switchgear, suitable for three-phase AC, rated voltage 10kV power supply system, used to accept and distribute power and control and protect the line.

IEEE

IEC

Energy Storage

Power

Proposition/Advantages

-

01

Mechanical endurance:Vacuum circuit breaker: 20,000 times;

Three position switch: 5,000 times; -

02

The IAC internal arcing is 31.5kA/s (A-FLR);

-

03

It can maintain rated insulation level and 1.1 times the through-flow capacity at zero gauge pressure;

-

04

Suitable for various harsh environments, such as high altitudes, high humidity, and high corrosion.

Technical Specifications

Download

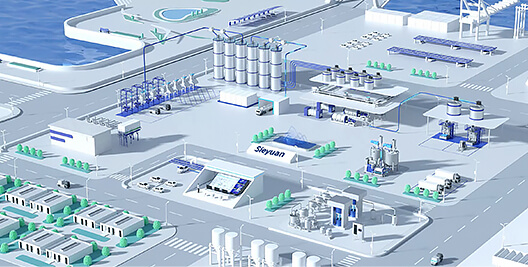

Related Programs

Related Cases

Tel : +86 (021)61610502

Start your consulting journey just one step away