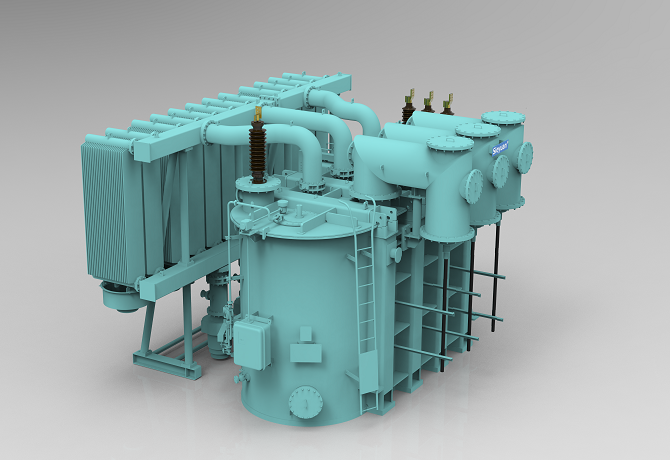

Power Transformer Solution

The company has fully introduced Toshiba's transformer technology, adopting design standards, work specifications, operating instructions, procurement specifications, and testing inspection criteria with Toshiba Japan. This ensures comprehensive capabilities in transformer design and manufacturing.

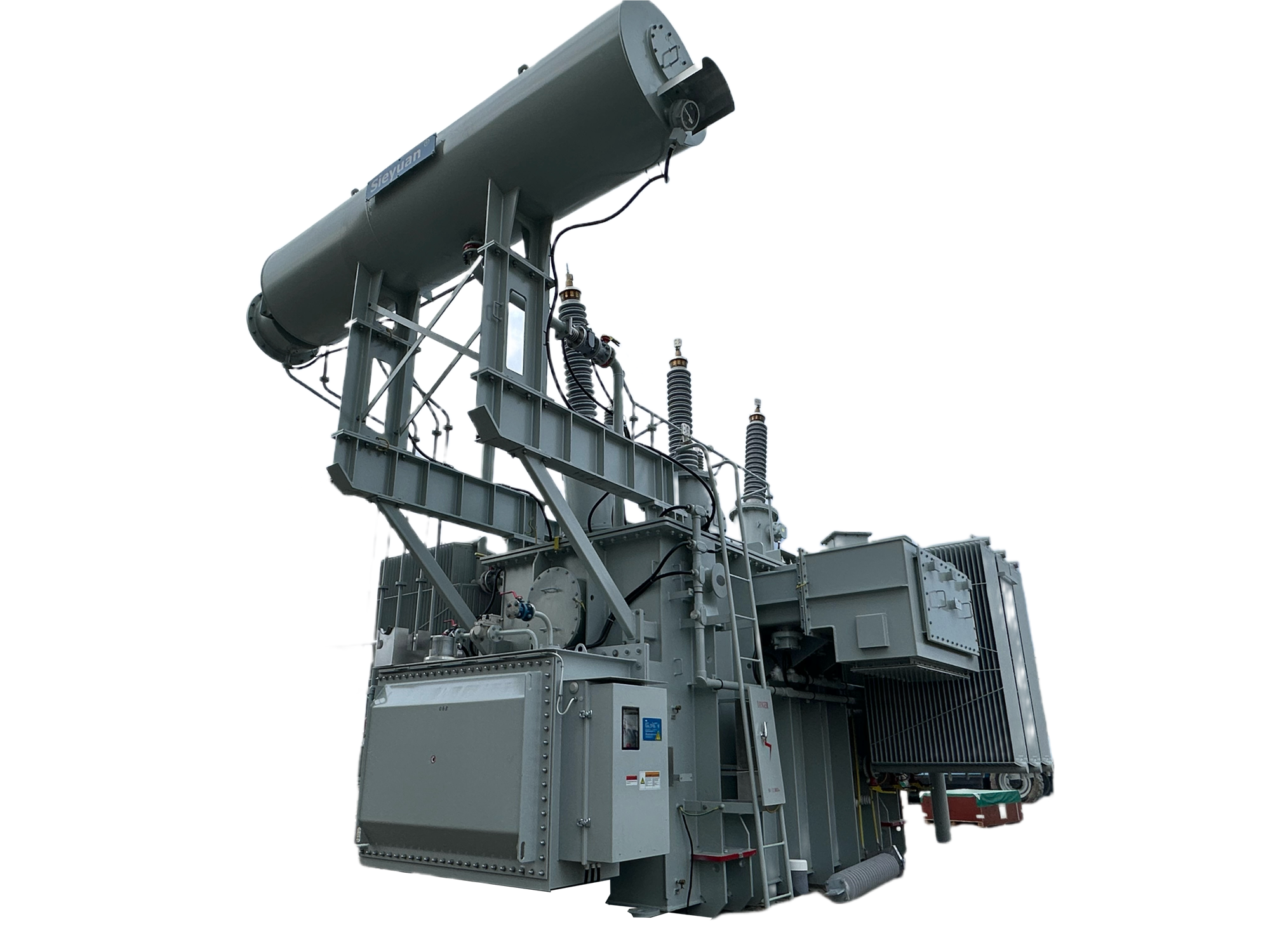

Description

Power transformers are devices used in power systems to transform alternating voltage and current for transmitting AC electrical energy. They primarily consist of material and components such as the core, windings, oil tank, tap changer, radiators, oil conservator, bushings, gas relay, etc. Mineral or eater oil are employed as both insulating and cooling media.

Key Benefits

-

01

Low Partial Discharge

By optimizing local electric field strength through electric field analysis, high-quality imported insulating components are applied to critical areas. High field-strength lead areas are shaped and shielded, while insulating and metal components undergo rounding or shielding treatments. Assembly environments are strictly controlled to minimize contamination.

-

02

Low Loss

Magnetic leakage analysis is used to determine optimal transposition methods for conductors. High-quality transposed conductors, magnetic shielding on clamps and oil tanks, magnetic isolation slots on clamping plates, and a six-step core stacking technique with mitered joints are employed. Longitudinal and transverse eddy current losses, as well as stray losses, are rigorously minimized.

-

03

Low Noise

HI-B silicon steel sheets, precision cutting lines, and full mitered six-step core stacking (increasing joint cross-sections and reducing air gap reluctance) are utilized. Automatical stacking ensures core noise performance. Using soft connections between non-load-bearing components to further reduce noise transmission.

-

04

Strong Short-Circuit Withstand Capacity

Short-circuit mechanical force analysis determines optimal coil support points. Self-adhesive transposed conductors, semi-hard copper wires, high-strength integrated insulation rings (Toshiba's patented technology), differentiated spacer counts for inner/outer coils, internal/external support strips, and rigid paper cylinders are applied. Pre-compacted molded horn spacers are used at transposition and incomplete winding points.

Application Scenarios

-

Power Grid and Power Generation

-

Industry

-

Rail Transportation

Related Products

Tel : +86 (021)61610502

Start your consulting journey just one step away